Our Services

Specialized Expertise for Commercial Vessels

Commercial vessels endure heavy use, rigorous duty cycles, and often harsh marine exposure. Repairing them requires more than cosmetic fixes. Pacific Fiberglass excels in:

-

Load-bearing structural repairs: stringer replacement, bulkhead reinforcement, deck/hull junction strengthening

-

Shell plating and hull restoration: patching or replacing sections of hull skin and shell plating

-

Bulkhead, deck, and superstructure repairs: restoring stiffness and integrity where delamination, impact, or fatigue have compromised the structure

-

Corrosion-resistant composite overlays: protecting areas subject to abrasion, cavitation spray, or chemical exposure

-

Watertight integrity repairs: fixing penetrations, patching leaks, reinforcing around fittings and thru-hulls

Our comprehensive services and approach balance robust materials and engineering rigor with a focus on minimizing downtime.

Why Pacific Fiberglass Stands Out

Pacific Fiberglass focuses intensively on commercial-grade composite repair systems that meet the standards and expectations of owners, insurers, and class surveyors.

Key advantages we bring:

-

Project-level engineering and structural analysis support

-

Controlled shop environment to reduce contamination or moisture interference

-

Composite specialists versed in epoxy, vinyl ester, and high-performance reinforcements

-

Integration with welding, mechanical, and metal trades for hybrid repairs

-

Full documentation, certification, and transparency for regulatory or insurer review

Our Process & Quality Assurance

-

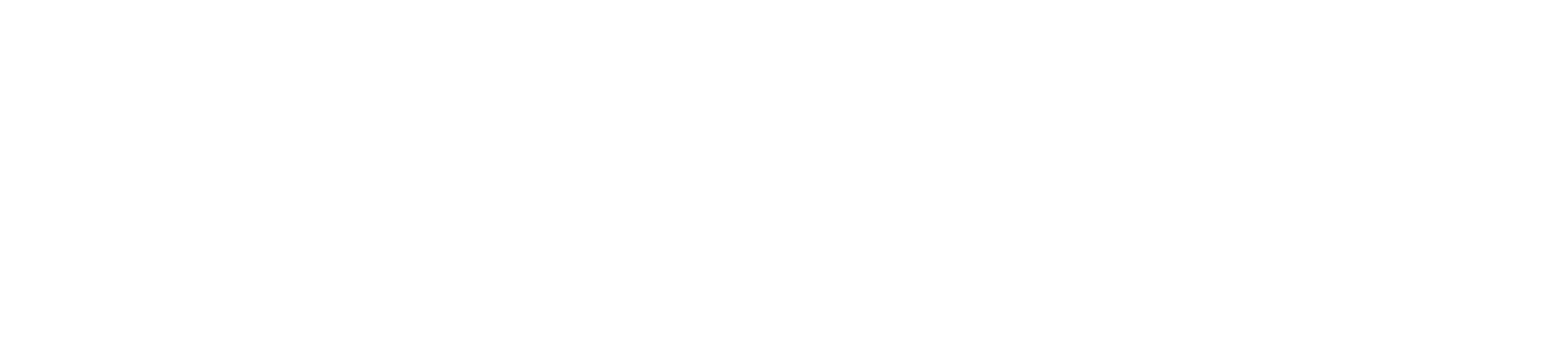

Initial damage survey & diagnostics

Using tools such as moisture meters, and borescope inspection, we map affected zones and detect delamination or hidden damage. -

Repair engineering plan

We develop repair laminate schedules, specify fiber orientation, joint design, and reinforcement layers aligned with original structural load paths. -

Preparation & scaffolding support

The vessel is suitably shored and stabilized; local removal of coatings or gelcoat is done only where necessary to access the damaged substrate. -

Composite repair execution

Working in climate-controlled zones, we perform stepwise composite lamination, core reinstatement, and hybrid metal interface repairs. -

Integrated trades coordination

When repairs interface with metallic structures, piping, rails, or hardware, we coordinate with welding, machining, and mechanical teams to ensure seamless integration. -

Inspection, testing & certification

Post-repair, we conduct non-destructive testing (e.g., tap tests, ultrasonic scans), monitor cure progression, and deliver final documentation and sign-off.

Industries & Vessel Types We Support

-

Workboats & crew transfer vessels

-

Tugboats and harbor support crafts

-

Ferries and passenger workboats

-

Offshore service vessels, dive support, patrol, and research craft

-

Barges, pontoons, and service platforms

Our Commitment to Reliability & Uptime

Commercial operators can’t afford extended downtime. That’s why Pacific Fiberglass emphasizes efficient scheduling, parallel workflows, and fast turnaround. We strive to deliver repairs that match or exceed factory strength while keeping your asset back in service as quickly as possible.

When you need composite repairs for your commercial fleet—structural work, hull rehabilitation, or hybrid reinforcement—Pacific Fiberglass is your specialist. Let us evaluate your vessel and propose a repair path rooted in technical excellence, durability, and marine service readiness.

Why Pacific Fiberglass Excels

Pacific Fiberglass emphasizes tailored composite modifications with structural discipline built in. We don’t just make things look right, we make them last.

What sets us apart:

-

A composite-first approach: every cut, flange, and interface is analyzed for fiber continuity, stress flow, and core integration.

-

In-house engineering support: we produce CAD layouts, perform finite element validation (as needed), and develop laminate schedules.

-

Controlled repair environment: modifications are executed in climate-controlled bays to prevent moisture entrapment, contamination, or resin anomalies.

-

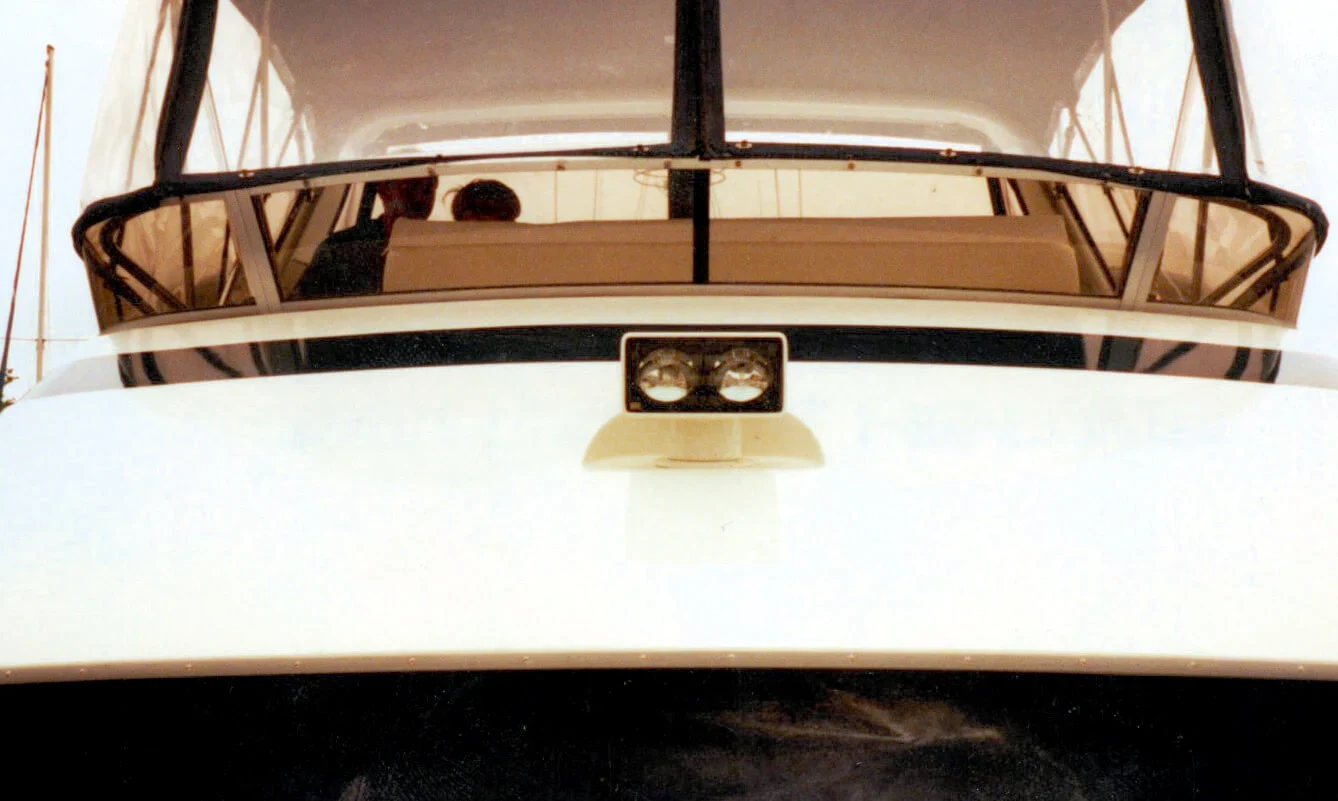

Seamless finish integration: modifications emerge with gelcoat, paint, or finish blends that align with the existing hull aesthetic.

-

Full documentation & QA: we deliver inspection records, test reports, and before/after imagery for your confidence and archival use.

Our Process: From Concept to Sea Trial

-

Consultation & site survey

We catalog your goals, take measurements, scan the hull geometry, and inspect the structural condition. -

Design & planning

We generate mockups, stress routing, reinforcement strategies, and interface connections. -

Masking & isolation

Adjacent surfaces are protected, and the work zone is masked to preserve surrounding finishes. -

Cutting, shaping & reinforcement

We carefully cut or open the hull structure as needed, install supporting backing, core, or stiffeners, and build the modification zone out with composite layups. -

Integration & finishing

After full cure, we fair surfaces, apply gelcoat or paint, and polish transitions for a flush, seamless appearance. -

Testing & validation

We pressure-test any waterway modifications, run functional checks, and obtain quality assurance sign-off. -

Sea trial/commissioning

You can test the new system in real-world conditions—we monitor, adjust, and certify its performance.

Let’s Modify with Purpose

Your vessel is a platform for both performance and expression. If you’re considering installing a thruster, extending swim platforms, retrofitting pods, or any custom modification, trust Pacific Fiberglass to deliver solutions that are intelligent, durable, and visually seamless. Talk to us, and we’ll bring your vision and your vessel into its best form.