Our Services

What We Do: From Fixes to Fabrication

Hull & Skin Repairs

When your hull is marred by impact, abrasion, blistering, or osmosis, we restore it to its original condition. Our technicians assess damage, remove compromised laminate, and rebuild with marine-grade fabrics and resins. The result is a restored shell that retains strength, integrity, and hydrodynamic fairness.

Gelcoat & Finishing

A structurally sound hull isn’t enough; aesthetics matter. We color-match and apply gelcoat with careful blending, sanding, and polishing to erase scars, match adjacent areas, and maintain a seamless finish. Whether patching stress cracks or dealing with cosmetic blemishes, we treat appearance as part of performance.

Custom Parts & Fabrication

Need a deck hatch, custom fairing, instrument pod, intake scoop, or ladder bracket? We produce custom fiberglass parts to spec. Using molds, plug patterns, or hand layup techniques, we ensure each part aligns with your vessel’s geometry, fits flush, and bonds reliably.

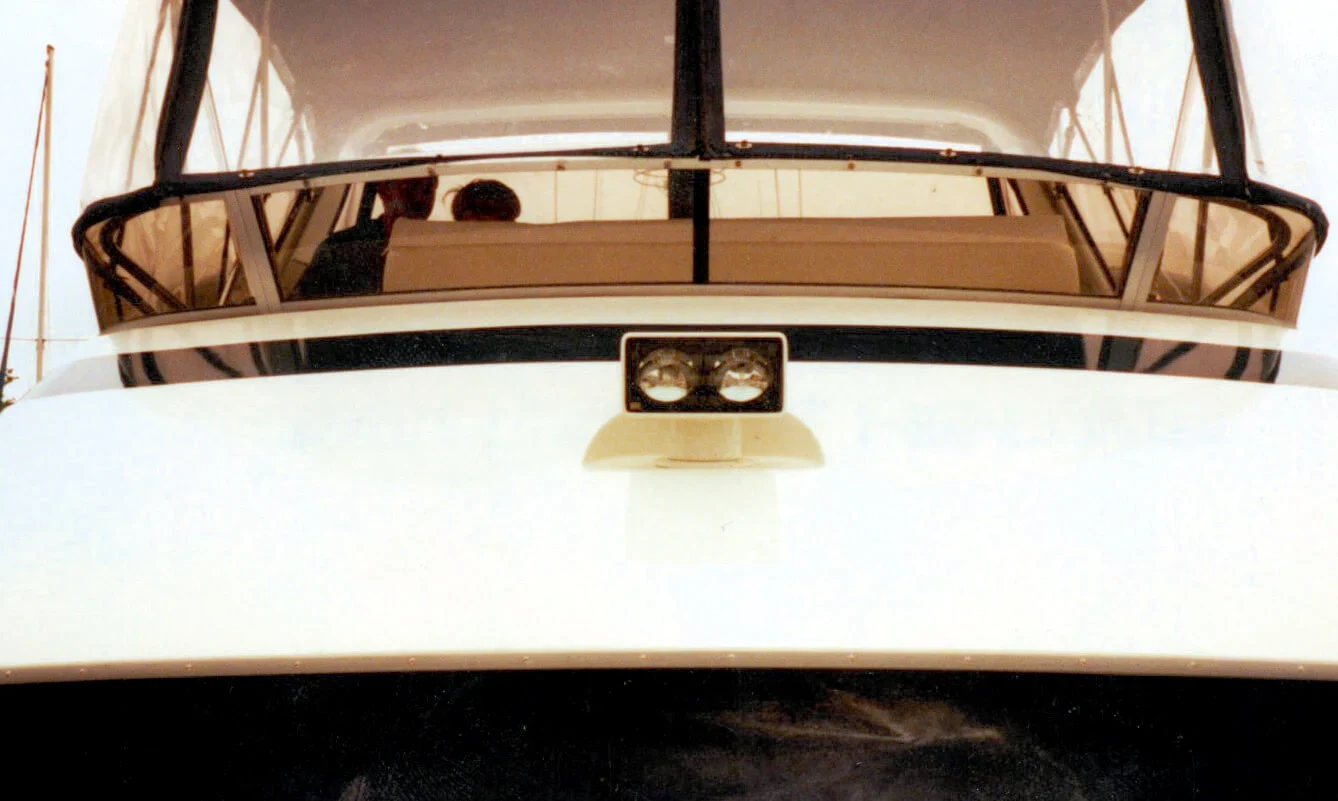

Thruster Tunnel & Bow Thruster Installs

Thruster tunnels demand precision. We cut, reinforce, and fit tunnels with accurate curvature, integrate with hull core and skins, and reinforce around openings. We also create flanged bolt-in mounting systems and custom fairings for seamless integration.

Composite Reinforcement & Overlays

We apply strengthened overlays — carbon, Kevlar, biaxial, or multiaxial fabrics — over areas that experience high stress, impact zones, wet exhaust cavities, or abrasion-prone regions. These overlays enhance durability without adding excessive weight.

How Pacific Fiberglass Delivers Value

At Pacific Fiberglass, we combine two essential elements that define quality marine repair—exceptional craftsmanship and rigorous structural discipline:

-

End-to-end control: We manage repairs from assessment through completion, avoiding fragmentation among subcontractors.

-

Precision repair workflows: We work in climate-controlled bays, use vacuum bagging where appropriate, and strictly control resin-to-fiber ratios.

-

Engineering mindset: Even cosmetic repairs are backed by structural awareness. We respect load paths, core continuity, and laminate schedules.

-

Quality assurance: Each repair or installation is inspected to verify bond integrity, thickness, and the absence of voids.

The Process You Can Expect from Pacific Fiberglass

-

Damage diagnosis & mapping

Using moisture meters, visual inspection and core samples when necessary, we precisely define the impacted area. -

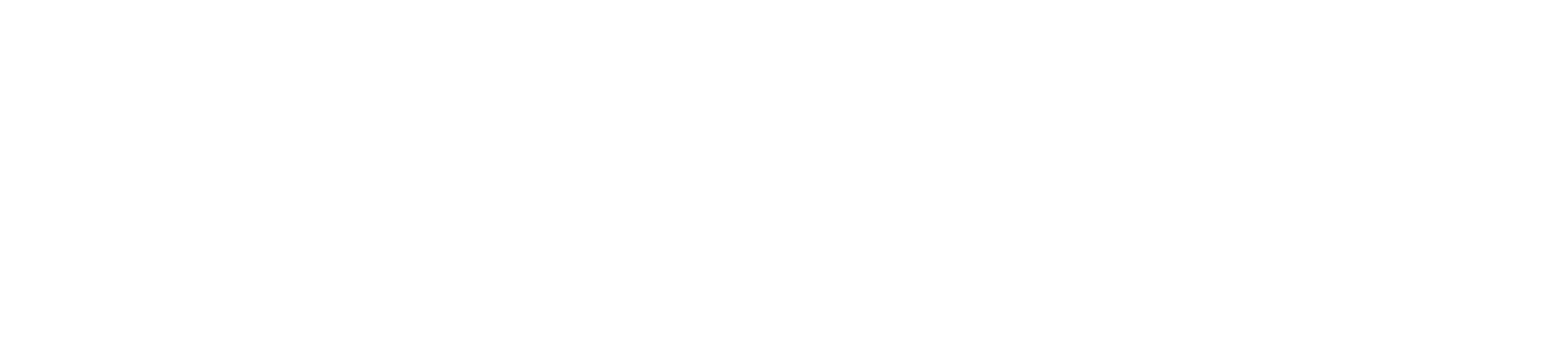

Cut-out and preparation

The damaged skin or core is selectively removed, the edges feathered, and the surfaces prepared for bonding. -

Layup & reinforcement

We carefully rebuild the laminate stack, integrating core, reinforcements, and skin layers in sequence. -

Fairing, finishing & gelcoat

After curing, we fair the surface and apply gelcoat, matching blends, color, and finish to the surrounding areas. -

Fit & integration of components

For installations (like tunnels or pods), parts are trial-fitted, trimmed, bonded, and sealed. -

Final QA & sign-off

We perform non-destructive checks, dimensional verifications, and ensure aesthetics meet high standards before release.

If you’re looking for a fiberglass specialist who can handle anything from a cracked hull panel to a new thruster tunnel or custom structural overlay, Pacific Fiberglass – Fiberglass Works is your partner. Let us bring precision, durability, and marine expertise to your next project.